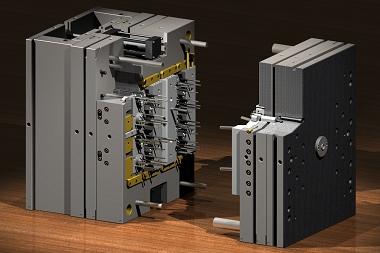

Mold Maintainance & Repair

For every type of mold, a regular mold maintenance schedule is required to keep molds ruuning at peak performance. Without the proper maintenance, molds will inveitable begin exhibiting problems that can be costly to fix and that can drastically reduce production efficiency. Ego has its own principles for mold maintainance.

Basic Maintenance

Basic preventative maintenance is done daily. We clean the mold, applying proper lubrication to moving components. We also check for damage and wear that would affect safe mold operation and part quality. This simple maintenance can be done while the mold is in the press.

Generaol Maintenance & Repair

|

Depending on the complexity of the mold, larger-scale general maintenance is usually done according to cycle count, or how many times the mold has been run.

We inspect the last shot of parts from the mold for damage or defects. If all is well there, we go ahead and disassemble the mold completely. The mold plates are cleaned and inspected for signs of wear, vent depths are checked, and O-rings are replaced. Any part of the mold that is defective or damaged is swapped out.

Special occation: mold equipped with hot runner, we check it for signs of leakage and inspect the condition of the components. Then we reassemble the mold, run a thorough systems check, and ready it for production or storage.

Email to our sales team today for your project info@ego-mfg.com

Major Maintenance & Repair

Every mold need a major preventative maintenance after a certain cycles. This process includes all of the steps donee in general maintenance and takes a much more in-depth look. We measure the mold's alignment features, compare them to their baseline 'new' condistion, and replace them as necessary. All other components are measured to the original print dimensions and put back to new condition. If the mold cavity finish is degraded at all, we refurbish it. When all is said and done, we rebuild the mold in better-than-new condition and put it back to work!

Regualr and proper completion of all three types of maintenance is the key to keeping our molds in excellent condition.

Mold Modification

Mold modification is often required during manufacturing, especially for new developed projects. Ego manufacturing group has professional mold builders and mechanists to analyse the possibility of modification our customer requires, and provide advises to customers. Using advanced machines to finish the modification after all agreed on both parties.

Mold modification is often required during manufacturing, especially for new developed projects. Ego manufacturing group has professional mold builders and mechanists to analyse the possibility of modification our customer requires, and provide advises to customers. Using advanced machines to finish the modification after all agreed on both parties.

Copyright © Ego Manufacturing Group All Rights Reserved | Sitemap |