Precision Machining Service

|

Our precision machining company is supported by our experienced specialists and CNC machinists who are experts in programming, fixture design, and development. Ultra-precision requires our machinists to possess a deep understanding of a machine’s behavior – not just programming and running in accordance with a manual. CNC machinists’ familiar with their machines give them the ability to push the machines beyond the manufacturers’ intended design and tolerance capabilities, maximizing their performance when needed. With knowledgeable, industry leading ultra precision machining professionals on our team, we have been able to develop processes achieving practically impossible levels of perfection with the manipulation of temperature compensation curves and control. Our customers receive the best precision components they need with the repeatable accuracy they demand. We perform a number of ultra precision machining services, such as:

|

-- Wire EDM

-- Super Precision Lathes

-- Sink/RAM/Plunge EDM

If you are looking for the sharpest, cleanest, and most precise CNC machining company in China, Ego Manufacturing Group has the capabilities you need to get your orders cut and delivered on time and cost effective.

Click info@ego-mfg.com to get a quote for precision machining project.

Wire EDM for Guaranteed Precision

Although it may initially be overwhelming, getting a handle on the full scope of CNC machining capabilities available and how they can benefit your products is easy once CNC techniques have been properly defined. Starting with wire electrical discharge machining (EDM), Ego Manufacturing Group would define an EDM machine as one of the most effective CNC indentation and cutting methods available today.

“EDM machining services utilize electrical discharges to make cuts in hard metals.”

Applications best suited for the EDM process are those characterized by extremely exacting tolerances, making it difficult or impossible to handle with any other material removal process. EDM machining is a no-contact and stress free process, meaning it is also best suited for making fragile parts unable to handle the stress of a normal CNC machining process. (Printer hammers, graphite electrode, miniature gears, and any part featuring honeycomb shapes).

Ego Manufacturing Group’s wire EDM engineers are able to achieve a one micron positional accuracy with EDM produced walls as thin as 0.010” (.254mm), can provide precise CNC machining solution for our customers. If you have an unusual design needing the impressively precise cuts of EDM, give Ego Manufacturing Group your call or email our team info@ego-mfg.com !

Wire Cut Precision Machining

With excellent positional accuracies, precision wire cut machining offers exactly measured cuts down to ½ a micron (0.00002”). With different wire diameters available for individual client orders, we can select the proper sized wire for your product, including:

-- 0.038mm Diameter Wire

-- 0.0508mm Diameter Wire

-- 0.1524mm Diameter Wire

Although our .006” diameter wire cut machining is most commonly requested by our customers, you can still receive excellent corner radius control with our 0.038mm diameter wires. If you are looking for other CNC precision machining services like our rotary axial precision wire cut work, they are available for your consideration as well. Email us today for your project info@ego-mfg.com!

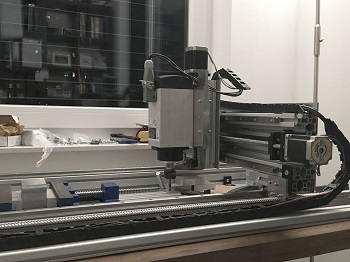

Evolved from the practice of rotary filling, 3 axis machining is an average manual milling technique cutting parts on three axes; the X, Y, and Z axes. The vertical 3 axis CNC milling machine has come a long way in its capabilities.

|

While many machines have a moving bed, the 3 axis milling centers stand still while the cutter itself operates instead. 3 axis models are multifunctional, accurate machines designed for:

-- Automatic / Interactive Operation

-- Milling Slots

-- Drilling Holes

-- Cutting Sharp Edges

3-axis milling is capable of creating the same products as 4 axis and 5 axis machines, but the 3 axis machines cannot deliver the same level of detail or efficiency as its predecessors. 3 axis can cut individual features during operations, but it cannot match the work of a 5 axis in quality or profitability.

4 Axis

Similar to the 3 Axis CNC vertical milling machine, 4 aixs micro-milling machines are vertically operated and built to function in a timely fashion. They are user friendly with manual and computer lead operations.

With the ability to operate on wood, foam, composite board, aluminum alloy, and even PCB, 4 axis is a multi0use CNC tool functioning at a slightly higher competency than the 3 axis.

Contact us to get an instant quote today info@ego-mfg.com!

Copyright © Ego Manufacturing Group All Rights Reserved | Sitemap |