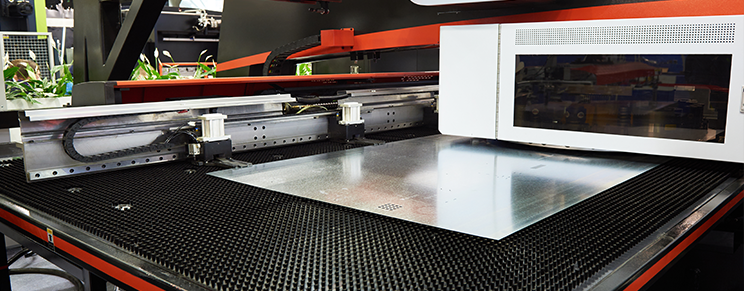

CNC Punching

Ego manufacturing group makes it easy to get your project done. With CNC punching, ego production team can produce customized unique designs from multiple thicknesses of various materials. We handle both short-run or long-run projects with the consistent quality, precision and on-time delivery. Ego has worked with the many industrie on many punching projects that require exact precision and quality.

Why Ego?

|  |

Ego delivers as promised, reflected by our many client awards. You can trust us to take your project as specified from start to finish. For complex parts, secondary operations such as countersinking, tapping, counterboring, louvres, surface finish and lance forms during punching reduces handling and makes EGO a more cost effective choice. There is no need to ship parts to another manufacturer if your projects requires fabricated parts like stampings, bendings, weldings, CNC machined parts, and punched parts, or molded plastic parts like roto molding, injection molding, blow molding and vacuum formings, we can take care of all metal parts in house, and sub-contract the plastics to reliable partners. So customers only need to contact one manufacturer only if dealing with us, and we will take care of the rest.

Contact us or email to our sales team directly for your project info@ego-mfg.com

Copyright © Ego Manufacturing Group All Rights Reserved | Sitemap |